A global player in the energy sector approached Habonim for a manifold valve solution. His traditional design uses multiple valves at different locations in the gas turbine, with long lengths of piping stretched throughout. This design creates a safety hazard due to poor controllability and complicated accessibility. The dispersed valves also require many interconnections, resulting in high installation costs and leak paths.

The Need

To design a reliable and compact valve solution which is able to:

- Secure gas tight shutoff

- Handle multiple pressure levels without internal backflow

- Manage a design temperature as high as 600°C

Sampling valves also had to be integrated into the manifold valve in order to measure and verify the turbine cleaning condition.

Habonim’s Solution

Habonim’s engineering team devised a manifold valve solution that offers all these features:

- Works in a confined space

- Guarantees minimum leak paths

- Incorporates a reliable locking system

- Modular design

- Cost-effective compared to traditional solutions

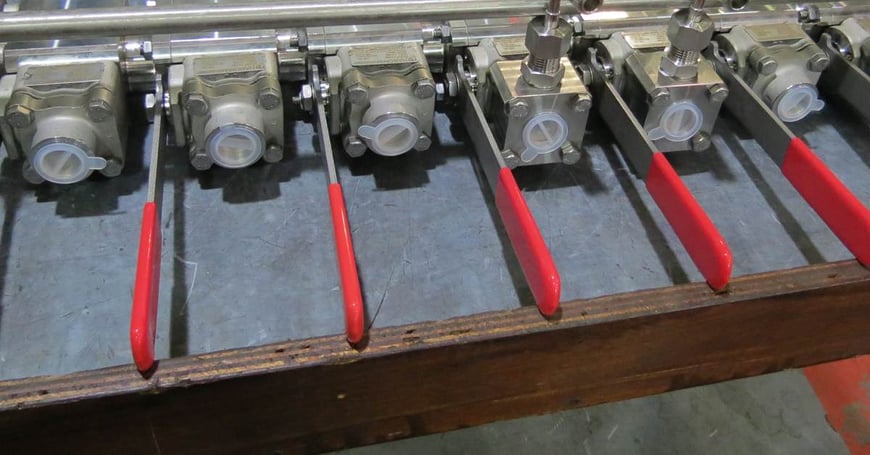

Using the unique fire-safe valve design as the basic module, Habonim designed an 8-valve, lockable manifold including 3 off-sampling ports (needle valves). The multi-port manifold design also incorporated a special locking device to ensure that all valves are closed when the turbine is in operation. A limit switchbox transmits a signal to the PLC system once the valves are closed and secured.

A special locking system was designed to securely lock all the valve handles during turbine operation

The machined manifold block eliminates the need for multiple welding and NDT-examination — increasing the accuracy of the block while reducing overall costs. The manifold configuration reduces to a minimum the number of leak paths and the risks of fugitive emissions, thus enhancing site safety.

The manifold has an extremely small footprint and is lightweight, allowing smooth in-situ installation of the unit. The accurately machined block allows for stress-free installation of the manifold valve to the gas turbine. Habonim’s manifold valve met all the customer’s requirements, delivering a cost-effective and efficient solution, which is performing in demanding applications.

You may also be interested in: