Transporting, storing or handling of small bulk LNG presents unique challenges. As the bulk size of payloads gets increasingly smaller, the size, weight, and mobility of transportation vessels, tankers and trucks have a major effect on the cost of acquisition, operation and maintenance. Add to that rigorous inland transportation regulations, the challenges of installation, operation and transportation within populated areas, and dealing with multiple municipal authorities, all of which raise the already high bar of required quality, safety and certifications even higher than in traditional LNG systems.

Traditionally, LNG systems, like other cryogenic media handling systems have been based on globe valves as the primary choice for media control and shutdown. However, globe valves pose some burdens on small scale LNG systems when compared to other valve types such as ball or butterfly valves. The Cv of the same valve size in globe style valves is smaller than in ball or butterfly valves. This affects the selection of overall piping size, as these valves frequently become a bottleneck in the system’s overall flow capacity.

Control globe valves require a linear actuation device both for shutoff and control, which are usually much more complex and costly when compared to a quarter-turn actuation device required to control and operate a quarter-turn style valve such as a ball valve. When you look at the valve-actuator package as a whole, this has a significant impact on the overall system complexity and cost. Emergency shutdown is another important function required in many LNG systems, which is clearly simpler and more efficient to carry out when based on a ball valve.

Systems are required to be small and lightweight, while maintaining maximal flow for shorter loads and offload operations. As such, the flow capacity of the bottleneck components have a growing impact on the total efficiency of the system. Ball valves provide a higher Cv when compared to a globe valve of the same size, providing a significant advantage as systems becomes smaller. Selecting a smaller size valve without losing flow rate allows the entire piping system to be reduced in size, with significant impact on the overall system size, weight and cost.

The Game Changer: Advanced Cryogenic Fire-Safe Ball Valves Serving Small Scale LNG Systems

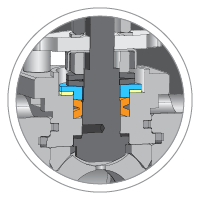

Bidirectional cryogenic floating ball valves offer all the benefits of a cryogenic valve coupled with the simplicity of floating ball valve technology. Cryogenic floating ball valves with bidirectional full Δp sealing capability allows it to be used on a bidirectional loading and offloading single pipeline as well as a shutoff valve for a storage tank, developing back pressure to the downstream side while empty without upstream line pressure.

Patent Pending – Habonim bidirectional cryogenic floating ball design is patent pending.

Optimal Actuation

Four piston pneumatic actuation technology carries some inherent benefits that make it ideal for SSLNG systems. Because it’s 50% smaller than an equivalent two piston actuator, it is much easier to fit it into a system with limited space, on the side or back of a tank placed on a track, railway cart or in a marine container (ISO container). HABONIM CompActTM robust four-piston pneumatic actuators guarantee hundreds of thousands of cycles without maintenance. Because they have approximately half of the piston stroke, open and close time is reduced and less air is needed for operation, while allowing smaller, more efficient auxiliary system support.

Four piston pneumatic actuation technology carries some inherent benefits that make it ideal for SSLNG systems. Because it’s 50% smaller than an equivalent two piston actuator, it is much easier to fit it into a system with limited space, on the side or back of a tank placed on a track, railway cart or in a marine container (ISO container). HABONIM CompActTM robust four-piston pneumatic actuators guarantee hundreds of thousands of cycles without maintenance. Because they have approximately half of the piston stroke, open and close time is reduced and less air is needed for operation, while allowing smaller, more efficient auxiliary system support.

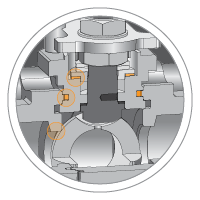

Emergency Shut Down

The combination of advanced cryogenic fire-safe quarter turn ball-valves with fast acting four-piston-based actuation creates the ultimate ESD package guarantee with long term operation capability and exceptionally fast reaction time. Once a ball valve is utilized for all system needs, fusible links for fire shutoff and use of the actuator’s integral springs for preloading and operation under loss of air pressure or other emergency conditions all become much easier to design and add to systems with the same valve styles.

The Total HermetiXTM Integrity Package

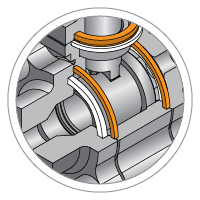

As a standard, all HABONIM cryogenic valves are equipped with the Total HermetiX integrity package comprised of three main elements and a superior inline sealing mechanisms in some of them:

The patented HermetiX stem sealing with zero fugitive emission sealing capability, tested and certified to ISO 15848-1 and API641 standards with up to 500,000 maintenance-free cycles life span.

Double body sealing for body-to-ends and for body-to-bonnet superior atmospheric sealing.

All fire-safe design that is tested and certified according to API 607 and

ISO 10497.

All HABONIM’s cryogenic valves are designed, tested and inspected according to BS 6364:1984 (amendment 3) standard and with the required TPED certified for transportable cryogenic and high-pressure valves. Type test approvals for marine service is provided according to each project’s specific needs. All Habonim ball valves are certified for API-6D (No. 6d-1278).

Habonim’s Bidirectional Cryogenic Floating Ball Valve offers safety, reliability and maintainability, together with all the necessary certifications for use in small scale LNG systems.