- Habonim HermetiXTM stem sealing

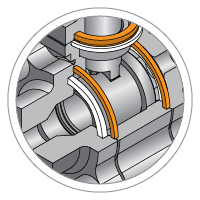

- Double body sealing

- Fully fire-safe construction

- Inline superior sealing

The Total HermetiXTM package with its unique design offers a higher level of integrity for the valves and systems. Here’s why its key standard features put it in a class of its own in terms of overall safety, proven reliability and enhanced environmental safeguards.

Double Sealed Body Ends & Bonnet

Double body sealing in all the valve’s potential leakage points to the atmosphere significantly increases safety, leakage prevention and valve integrity. An inner (primary) body seal is made of TFM and an outer (secondary) body seal that is made of graphite for fire-safe compatibility is installed on all the valve body connections, end connections to body, and bonnet to body connection where applicable. Seals can be manufactured from other polymers per customer request.

Double body sealing in all the valve’s potential leakage points to the atmosphere significantly increases safety, leakage prevention and valve integrity. An inner (primary) body seal is made of TFM and an outer (secondary) body seal that is made of graphite for fire-safe compatibility is installed on all the valve body connections, end connections to body, and bonnet to body connection where applicable. Seals can be manufactured from other polymers per customer request.

The inner polymeric body seals separate the media flow from the graphite-based outer seal, thereby guaranteeing no graphite particles overflow to the wet parts of the valve holding the media, while preserving the fire-safe capabilities of the valve.

Zero Fugitive Emission Certified stem Sealing with Up to 500,000 Cycles Without Maintenance

HABONIM patented HermetiXTM stem sealing system is zero fugitive-emission & tested, certified for ISO 15848-1 and API 641 standards, and has a proven tested capability to allow up to 500,000 cycles with no maintenance. The HermetiX stem seal is ideal for supporting high cycle actuation with maximal sustainability under ongoing wear and tear. Combined with Habonim CompAct actuators, the HermetiXTM stem seal is proven to operate with no leaks for millions of cycles in the toughest industrial applications.

HABONIM patented HermetiXTM stem sealing system is zero fugitive-emission & tested, certified for ISO 15848-1 and API 641 standards, and has a proven tested capability to allow up to 500,000 cycles with no maintenance. The HermetiX stem seal is ideal for supporting high cycle actuation with maximal sustainability under ongoing wear and tear. Combined with Habonim CompAct actuators, the HermetiXTM stem seal is proven to operate with no leaks for millions of cycles in the toughest industrial applications.

Fire-Safe Certified

The fully fire-safe tested and certified design meets ISO 10497, ISO API 607 and API 6FA international fire-safe standards. The HermetiXTM stem seal and the valve design for inline and external leakage prevention under fire conditions is fully fire-safe tested and certified and has been used successfully by the most demanding customers for the most demanding applications for decades. Over the years, HABONIM fire-safe designs has been successfully proven and certified repeatedly by type testing undertaken by a wide variety of certification bodies for marine, cryogenic, aerospace, oil and gas, biopharma, chemical and other uses.

The fully fire-safe tested and certified design meets ISO 10497, ISO API 607 and API 6FA international fire-safe standards. The HermetiXTM stem seal and the valve design for inline and external leakage prevention under fire conditions is fully fire-safe tested and certified and has been used successfully by the most demanding customers for the most demanding applications for decades. Over the years, HABONIM fire-safe designs has been successfully proven and certified repeatedly by type testing undertaken by a wide variety of certification bodies for marine, cryogenic, aerospace, oil and gas, biopharma, chemical and other uses.

Inline Superior Sealing

A verity of advanced inline sealing techniques are used by Habonim to extend the capabilities of the valve sealing for bidirectional sealing, full Δp operation, high & low pressure leak tightness, minimize operating torque and more.

Dynamic seat technology, hybrid seats and other techniques are used and combined to supply breakthrough sealing capabilities with minimized operation torque and cost effectiveness, elevating the valve safety and minimizing the overall system fugitive emission footprint.

Some of these designs are patented or in patent pending status.

Setting a New Integrity Level

All the Total HermetiXTM features are built into the Habonim valves as a standard in most of the product lines, offering a full variety of sizes and valve styles and wide pressure and working temperature range — allowing the use of a standard HABONIM valve to cover a wide range of valve needs in industrial and in most demanding applications.

Significant Cost Savings

Because Habonim’s Total HermetiXTM package is incorporated as a standard within our valves, a single valve type with a variety of end connections offered on the same valve body can be used to cover regular and fire-safe applications. This enables a reduction in the number of different valve types in use or in stock, simplifies maintenance, and enables a reduction in the total cost of ownership.

The high durability and minimal (or no) maintenance of HABONIM valves and CompAct actuators increases the overall cost savings of operating control and piping systems for diverse industrial uses and especially in high-end and demanding applications.

Decades of Proven Performance

Habonim has accumulated decades of lessons learned and experience with customers and product operation. Our product performance has been proven in systems within diverse industries and in the most demanding regulations and physical conditions. That experience is incorporated into our valve and actuator designs, material selection, manufacturing and processes, providing users with confidence in well-established products that perform in demanding applications.

Total HermetiXTM means total confidence that Habonim’s standard valves will perform in the most demanding applications, year after year.