Emergency Shutdown (ESD) systems are used in applications such as refineries, power stations, mining, liquefied gas transportation, hazardous plants, and nuclear plants where Safety Integrity Level (SIL) loops are mandatory. These systems offer a vital layer of protection that is designed to minimize the effect of critical scenarios and ensure safe operations by enabling the emergency shutdown of operations to protect personnel, the environment, and assets.

ESD systems usually include an emergency shutdown (ESD) valve and an associated actuator. As these systems are required for critical function in a process or project, it’s important that these components meet stringent international quality and safety standards.

ESD System Integration

At Habonim, we have the expertise to build optimized ESD packages in order to meet the strictest safety standards. Our ESD packages are certified to work in a SIL3 loop, providing reliable and rapid closure in the case of a system malfunction. At the core of our ESD packages is Habonim’s unique fast-action COMPACT™ actuator With its unique four-piston design, the COMPACT™ actuator has

a reduced pinion diameter, which significantly shortens piston travel. This actuator is ideal for ESD systems as it offers the fastest shutdown speed on the market of less than one second, as well as a 7-year warranty with millions of cycles before maintenance is required. In addition, we offer seamless integration of the COMPACT™ actuator into ESD systems and are able to dramatically improve its standard shutdown time.

This quarter-turn rack and pinion actuator doubles the torque of standard pneumatic actuators, which only have two pistons. The superior performance is achieved by Habonim’s patented four-piston design, which generates torque around a centrally-located piston. This translates into double the power for the same size actuator or half the size for the same amount of power.

How does it work?

The COMPACT™ actuator has four small cylinders, each located on one of the four sides of the cube. The smaller pinion and shorter travel distance of the pistons in the actuator require less air pressure than a larger, double-piston actuator to produce the same torque output. The end result is faster response times for emergency shutdown, lower air pressure for operation, and reduced maintenance.

Case Study: Fire Block Valves (FBVs) in Cryogenic Environments

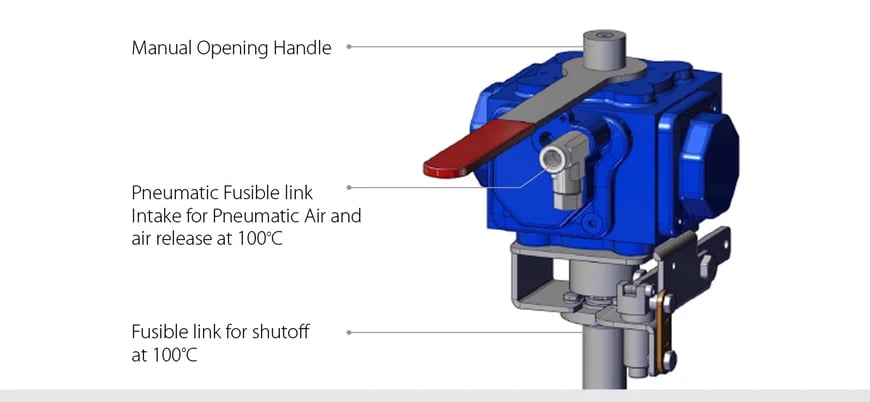

An example of a specific application for an ESD system is in the transportation of liquefied gases in a cryogenic temperature. Due to the inherent risks of these flammable and often toxic substances, a unique ESD system is required to isolate them in the event of a leak and to reduce the potential of fire or explosions. Habonim offers a Fire Block Valve (FBV) specifically for these applications, which combines a cryogenic valve with the COMPACT™ actuator.

When transporting liquefied gases, all valves and instruments on the containers need to be in a closed position, including the first valve on the liquid line – the ball valve with the Fire Block system installed. The FBV valves cannot be left in an open position for longer than what is required to fill and discharge the containers. The FBV is opened before filling and is left in an open position for the filling process. Once the filling process is completed, the valve is closed and is left in a closed position until the container reaches its destination. At the final destination, the valve is opened before the container is discharged, and after the discharge, the valve is closed and is left in the closed position until the container is transported to the filling plant.

Each filling and discharge opening in portable tanks used for transporting flammable, refrigerated, liquefied gases needs to be fitted with at least three mutually independent shut-off devices in series. The first is a stop-valve that is situated as close as possible to the jacket. The second is also a stop-valve and the third is a blank flange or equivalent device. The shut-off valve closest to the jacket needs to be a quick-closing device that closes automatically in the event of unintended movement of the portable tank during filling, discharge, or fire engulfment. It also needs to be possible to operate this valve remotely.

Habonim performs in the most demanding applications

Chart Ferox, a leading global brand for the design and manufacture of highly-engineered cryogenic equipment, contacted Habonim with a request to supply FBVs because of the company’s proven track record for performing in demanding applications. The valves needed to be robust and withstand the harsh conditions of a cryogenic environment, have the option for manual operation, pneumatic operation, and remote control; include a quick-acting emergency closure; and have a stop valve for cases of fire engulfment (temperature trigger). To ensure that all valves met these requirements, Habonim performed the following tests:

- Verification of brake temperature (100° C) of the fusible link at Ambient and Cryogenic

- Verification of the design of the locking mechanism of the fusible link at Ambient and Cryogenic

- Check if selected actuator matches the fusible link mechanism

- High pressure (105 Bar) test closure test at Ambient

- Back seat test (77 Bar) at Ambient

- Operational open manually under 0,5,10,15,20 Bar at Ambient

- Cool down to ‐196 °C until thermal stability

After the initial supply of FBVs to Chart Ferox, Habonim continued to perform ongoing testing and quality assurance, and to customize its products for the specific project requirements based on the test results and additional feedback from the customer. Once again, Habonim proved its reputation as a supplier of solutions that perform with unmatched reliability, stability, and safety in the most demanding applications.

Habonim has a long track record of supplying certified FBV-based ESD solutions for global leading brands such as Chart Ferox, PJS Turbogaz, Solar Turbines (a Caterpillar Company ), Siemens, GasCon, and China International Marine Containers (CIMC). All Habonim valves meet the Type Approval Certificates for Marine standards by DNV-GL, LR, BV, RINA, and KR.

%20systems.webp)

%20Valve.jpg)