Suppliers that regularly implement and maintain the highest standards for quality systems and practices, and continuously undergo auditing and approval by stringent safety and quality assurance bodies, give their customers significant added value and peace-of-mind.

For this reason, in critical-performance sectors, one of the most important components in system design is the selection of product suppliers. Every person involved in deciding what products to use in systems that function in extreme conditions needs to take multiple factors into account, with industry standard compliance being one of the most important.

There are multiple industry standards that need to be implemented, as well as specific standards for different segments. Companies can choose to work with and coordinate between lots of different suppliers that follow different industry standards and/or specific standards for niche segments. Or, they can work with a single supplier that gives them peace-of-mind by continuously implementing the most demanding quality industry and niche-specific standards and undergoing regular auditing and approval by recognized external certification bodies.

Habonim Follows a Wide Range of Recognized Industry Standards & Sector-Specific Standards

Habonim manufactures valves and actuators for a wide range of strategic sectors that require multiple industry standards and certifications, as well as specific standards for each sector. With an in-depth understanding of the complexities involved in following these varied standards, Habonim carefully selects and implements both the required industry standards and the standards specific to the sectors and segments it serves. This gives its customers the peace-of-mind they need to design solutions that meet the most stringent industry standards.

Habonim implements and follows these standards in all of its quality, design, manufacturing, and testing processes. This enables the company to design, manufacture, and supply ball valves and actuators for systems that function in extreme temperatures, pressures, and severe services; use hazardous materials; and where system performance is critical with the confidence of safety – and with the highest quality and reliability for the end-users.

These products are designed to control the flow of various gases and liquids in diverse markets, and improve the overall safety, integrity, and sustainability of the systems in which they are installed and are backed-up by third party certification to assure their best performance.

Habonim also follows the relevant laws, standards, and regulations to preserve the environment and promote sustainability (ISO-14001), and to promote occupational health and safety for its employees (ISO-45001).

Quality Management System

Habonim delivers the highest quality products to meet and exceed customer expectations. To this end, the company operates, instructs, and trains its employees globally to work according to international quality standards in all departments and throughout the product lifecycle. These quality standards include:

- General industry quality system standards:

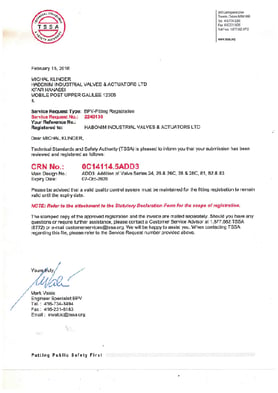

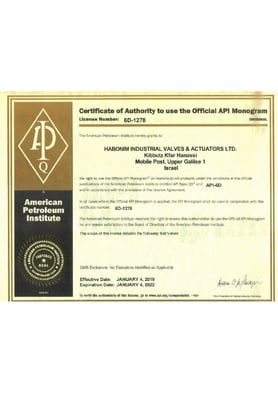

- API-6D (no: 6D-1278) – renewed in 2019

- ISO 9001 Quality Management – renewed in 2019

- Safety and quality system standards for specific market sectors and segments:

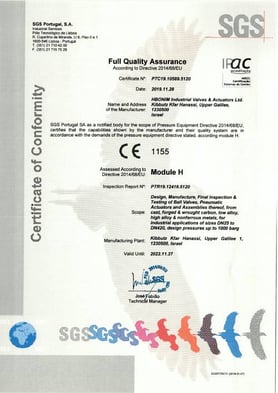

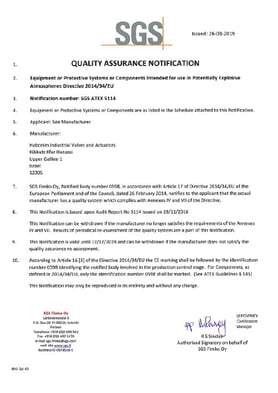

- CE-PED 2014/68/EU for pressure equipment – renewed in 2019

- ATEX 2014/34/EU for explosive environments – renewed in 2019

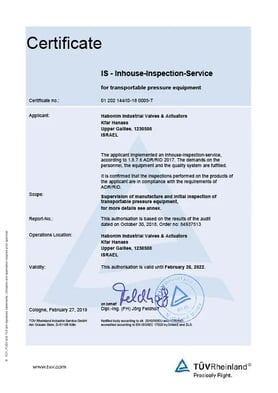

- TPED 2010/35/EU for the transportation of pressure equipment for applications such as cryogenic and compressed gas – renewed in 2019

As part of its unique way of conduct, Habonim also carries out external and internal testing and certification of products per customer request and market trends on a regular basis, and offers a wide range of certified products by leading global and territorial certification bodies such as: ABS, Lloyd’s Register (LR), Korean Register (KR), DNV-GL, China Classification Society (CCS), Korea Gas Safety Corporation, and RINA.

The company’s management monitors and audits all quality goals and objectives, and continually enhances processes and products to comply with the most stringent international accreditation and standards requirements.

Comprehensive and Application-Specific Certified Quality Approach

Habonim implements recommendations and follows international standards at every stage of the product lifecycle – from the initial stages of material sourcing through to design, manufacturing, assembly, packaging, and distribution, as well as testing throughout all processes.

Habonim has followed this implementation philosophy for decades, and as a result, customers trust Habonim with all of their regulation and certification needs, and rely on Habonim products for use in critical processes.

Products are designed, manufactured, and tested according to general international industry standards such as API-6D (no: 6D-1278), as well as specific standards for strategic market sectors and segments such as:

- Cryogenic and compressed gas segment:

- The TPED 2010/35/EU regulation is followed for products used to transport liquid and compressed gas. Some of the product lines for this segment also undergo type approval by external notified bodies.

- Design, testing, and inspection of these products are done in accordance with BS 6364:1984 (amendment 3), testing EN 14432:2014, and testing EN 1626-2008.

- Products for cryogenic applications are meticulously cleaned and assembled according to international standards specific to this segment (ASTM A380, CGA G-4.1, and EN 12300) in order to eliminate any ignition hazards that can be caused by the presence of hydrocarbon oil, grease, and metal chips.

- High-purity ball valves, which are cleaned in accordance with CGA G-4.1, and cleaned, dried, assembled, and packaged under clean room conditions, are also available for gas and water distribution applications, and chemical handling processes.

- Biotech sector: The ASME BPE standard is followed for this sector and the 3A sanitary standards in the implementation processes for the food and beverage segment.

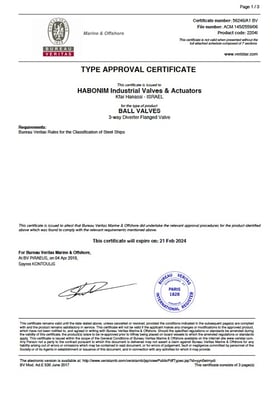

- Marine sector: Valve series for this sector are designed and certified through various type approvals by international notified bodies such as ABS, LR, DND-GL, BV, RINA and more.

- Oil & gas: API-6D (no: 6D-1278) and the API Spec Q1 standard for products supplied to this sector. This enables Habonim to supply valves for high-profile and critical-performance projects such as the Leviathan natural gas reservoir project.

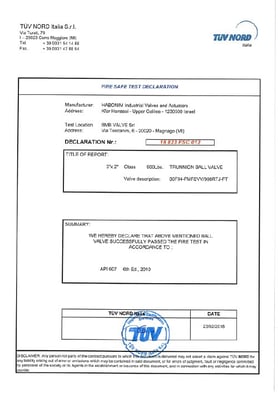

- Explosive and fire-hazard environments: Valves to be used in severe service, explosive, or fire-hazard environments are designed, manufactured, and tested according to the relevant standards, which include fire-safe API 607 and ISO 10497, API 6FA, and ATEX 2014/34/EU standard for explosive environments.

Raw Material Handling

All materials are sourced from well-known manufacturers with the required testing, documentation, and certifications, including:

- Materials certificates per EN 10204 type 2.2/3.1/3.2

- FDA/ EC 1935 compliant for polymers, elastomers, and lubricants

Product Traceability

During the manufacturing and assembly processes, all products are tagged with a stainless steel nameplate for full traceability, and heat numbers and material certificates are tracked to enable full backtracking of product components. Traceability of assembly and testing procedures, heat codes, and foundry identification are implemented and managed as per the applicable standards for each market.

Developing and Supplying Effective, Safe, and Reliable Products for High-Performance Applications

Habonim is committed to designing, manufacturing, and supplying the highest-quality solutions for cryogenic, emergency shut-off, high-pressure, and severe-service applications. The company serves global leaders in the oil & gas distribution, severe service, marine, and biotech markets; and works continuously to improve, enhance, and expand its capabilities and products to meet and exceed its customers’ expectations.

This commitment has led Habonim to implement and follow the most demanding standards as an integral part of its code of conduct.

Read about standards & certifications on the Habonim website.