Habonim latest Cryogenic Bi-Directional Floating Ball Valves as our extended products range for Cryogenic applications.

Over the last three decades Habonim has developed and supplied high-end cryogenic ball valves for a variety of applications and industries. In the last decade cryogenic applications become much more popular, heavily driven by the growing use of Liquefied Natural Gas (LNG) fuel that drives a constant need for advanced technologies that will enable building much more affordable cryogenic systems with a higher ROI.

The markets of Small Scale LNG (SSLNG) and LNG global trading are growing on an unprecedented scale.

By closely cooperating with some of the market leaders in cryogenic systems and equipment manufacturers it became apparent that floating ball valve technology has some clear advantages over other legacy valve technologies, with higher flow rates, simpler automation, durability, and cost.

The one aspect that cryogenic floating ball valves used to have as a downside was their unidirectionality inherited from their inner-ball pressure relief hole. But, this is not the case anymore.

Habonim has developed and is successfully supplying its patented Bi-directional Cryogenic floating ball valves. As these technologies have now extended making it available in most of Habonim's Cryogenic floating ball valves product series, the use of Bi-directional Cryogenic floating ball valves become even more natural. Read and learn more.

|

Cryogenic Bi-directional floating ball valves. They enable a single pipeline to perform loading as well as offloading which eliminates the need for two separate pipelines hence dramatically reducing installation cost and time. The same valve can act as a shutoff valve, allowing an upstream pipe offloading without excessive pressure buildup. |

Why a typical cryogenic floating ball valve is uni-directional?

In an open position, the media flows inside the valve, around the ball, filling the valve cavity area.

As the valve is turned to close position, the pressure increases from the upstream side, the ball is pressed against the seat and a sealing surface is maintained between the ball and the seat as well as the back of the seat and the body of the valve. the flow is cut off, yet the inside of the ball and valve cavity stays full of the media that is now trapped between the two seats on both sides of the ball.

Cryogenic media is often a liquid, as temperature changes in the valve cavity this might turn the trapped media inside the valve cavity into gas, that evaporation extends the volume of the media dramatically. As this media is trapped in the valve cavity, it might increase the inner pressure inside the cavity to an unwanted level.

A relief hole in one of the sides of the ball, allows the over pressurized media to evacuate into the pipe, balancing the inner pressure and preventing this unwanted overpressure buildup in the valve cavity area. This hole makes this valve unidirectional as it allows free flow of media on that side of the ball and no pressing of the ball into the seat to make a tight seal between them.

The benefits of ball valves and floating ball valves

Any ball valve allows much higher flow rates when compared to globe valve. Although being the legacy primary valve type in use for cryogenic piping systems, its relatively low flow rate requires the valve size to be scaled up to allow a certain flow rate, consequently the entire piping needs to be scaled up to meet the valve size, as the valve flow rate dictate the system flow rate.

Design around a ball valve with a much higher flow rate per size of valve, allow using a smaller valve without losing flow capacity of the system. In fact, the entire piping system size can be reduced to meet the flow rate of the valve and the result is a "smaller", lighter and less costly system that has the same flow capacity as with the bigger size globe valve.

When talking about ball valves, they can be either a Trunnion-ball style or a floating-ball style.

As explained, traditional floating ball valves for cryogenic use will be uni-directional, hence a trunnion ball is required to maintain a bi directional sealing. Trunnion ball valves are much more complex, require more maintenance and are much costly when compared to floating ball valves.

How significant can the impact of using a floating ball valve be?

Some cryogenic, and LNG specific systems Habonim was involved with redesigning to replace globe valve technology with floating ball valve technology, have resulted in up to 60% reduction in the total system cost, lower footprint.

Weight, mechanical support, and much more simple to automate.

Have it all! Cryogenic, Floating-ball, Bi-directional sealing.

As this industry evolves, new system designs are applied with the need to have Bidirectional sealing and the benefits of floating ball valves, Habonim has developed solutions that allow a simple floating ball valve design to allow cryogenic bi directional sealing and prevent an inner cavity over-pressure buildup- thus offering the benefits of a floating ball valve with the benefits of bi directional sealing with an optimized performance-to-cost ratio.

Solution No. 1- Based on Self-releasing spring-loaded seats design:

The seats are loaded with springs from each side together with integrated seal that is connected to the seat, above a certain pressure the seat will get some small deformation against the spring making it go back a little and release the cavity pressure to the pipe. Once the pressure is relieved the spring brings the seat back to its original shape and the valve is ready for a new cycle. This patented solution is offered as part of Habonim's C47 three-piece valve series in sizes up to 2" (DN50). and for pressure ratings up to class 300 (50 bar). In this solution the pressure may be relieved on either side of the pipe – upstream or downstream.

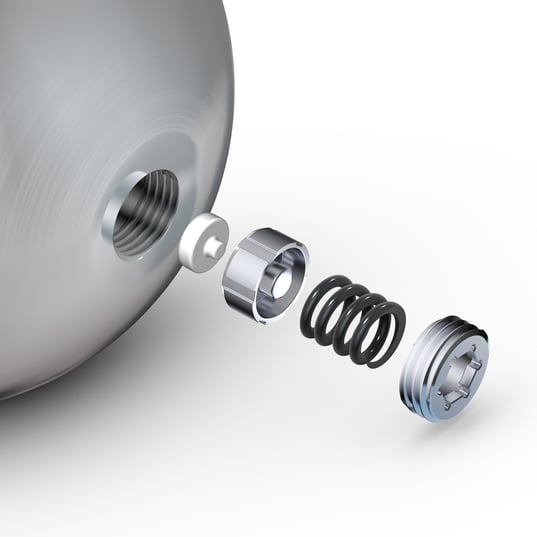

Solution No.2- In-ball embedded Pressure Relief Valve (PRV) device:

This patent-pending technology enables converting virtually any cryogenic floating ball valve into a bidirectional Cryogenic Floating Ball Valve, by replacing the ball with the hole with an integral PRV device ball.

Simple as that!

How does the Integral Pressure Relief Valve work?

PRV performs similarly as a check valve that allows media flow from the cavity upstream at a preset pressure to eliminate excessive pressure build-up at the cavity.

The integral PRV device in the ball is set up to work in accordance with the valve's maximum working pressure class and will prevent any access pressure of the valve body. Once the pressure inside the cavity is back to normal values, the PRV goes back to closed position to ensure valve performance in accordance with its pressure rating.

Bi directional Cryogenic design is based on this unique design of PRV that is embedded inside the ball and is offered by Habonim in all Cryogenic floating ball valve series, size 2.5" and above.

A mark is placed on the valve’s body and bonnet to indicate PRV location, which dictates the direction the pressure is relieved to.

Want to talk with our experts? Click on the link >>